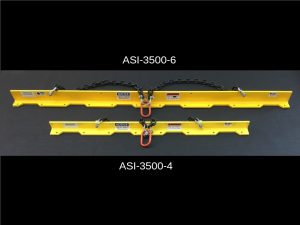

The ASI-3500 Series Lifting Beams are designed for both removing heads and installing new heads on 3500 series engines safely and more efficiently. The mechanic removes the manifolds, the valve covers, etc., to get to the heads, breaks the head loose from the block and installs the lifting beam. The crane does the heavy lifting work 2, 4 or 6 heads at a time depending on the Lifting Beam they apply to the job.

The ASI-3500 Series Lifting Beams are designed for both removing heads and installing new heads on 3500 series engines safely and more efficiently. The mechanic removes the manifolds, the valve covers, etc., to get to the heads, breaks the head loose from the block and installs the lifting beam. The crane does the heavy lifting work 2, 4 or 6 heads at a time depending on the Lifting Beam they apply to the job.

Here the ASI-3500 Lifting Beam is used to lift 4 3500 series heads from the truck to near ground level where the mechanic will clean the heads, install new fittings, install roller cam push rods, and make ready for installing onto the engine block. The heads then move to the engine block where pin to head alignment is very close if not right on. The heads settle onto the engine block and are torqued down.

Here the ASI-3500 Lifting Beam is used to lift 4 3500 series heads from the truck to near ground level where the mechanic will clean the heads, install new fittings, install roller cam push rods, and make ready for installing onto the engine block. The heads then move to the engine block where pin to head alignment is very close if not right on. The heads settle onto the engine block and are torqued down.

Whether removing or installing heads, it pretty much looks like this. Heads are attached to the Lifting Beam with handles provided in the kit, or mechanics often use 3/8″ bolts to make this task even faster.

Whether removing or installing heads, it pretty much looks like this. Heads are attached to the Lifting Beam with handles provided in the kit, or mechanics often use 3/8″ bolts to make this task even faster.

Some after market services companies resort to using a octopus sling to move more heads at once. This is a dangerous method as the heads are not controlled and literally bang into each other as well as result in loose heads being suspended above the mechanic at the engine block. The ASI-3500 Series Lifting Beam was designed to eliminate the use of single swing and octopus swing operations.

Some after market services companies resort to using a octopus sling to move more heads at once. This is a dangerous method as the heads are not controlled and literally bang into each other as well as result in loose heads being suspended above the mechanic at the engine block. The ASI-3500 Series Lifting Beam was designed to eliminate the use of single swing and octopus swing operations.

Improving safety on the job, providing the best tools and gaining efficiency is what we do. The ASI-3500 Series Lifting Beams are affordable, efficient solution for moving 3500 series heads while greatly improving safety.

Improving safety on the job, providing the best tools and gaining efficiency is what we do. The ASI-3500 Series Lifting Beams are affordable, efficient solution for moving 3500 series heads while greatly improving safety.